Blog

Dynabrade has partnered with Renny Doyle, of Detailing Success, to bring you an all new geared dual-action polisher that cuts like a rotary and finishes like a DA. Dynabrade is excited for this partnership and the innovation this adds to our tool lineup.

In the dynamic landscape of modern business operations, the quest for tools that seamlessly integrate efficiency, safety, and cost-effectiveness has become paramount. Pneumatic tools have emerged as a strategic solution, garnering attention across diverse industries.

Embrace a sustainable approach with recyclable aluminum, meeting the demands of modern industries for reliability and environmental responsibility by discovering the strategic advantages of aluminium housing.

Dynabrade’s new aluminum housing extension die grinders are built for tight spaces and deep channels. Featuring a featherable trigger, durable anodized aluminum body, and low-noise exhaust, these tools are ideal for aerospace, metalworking, and more—lightweight, precise, and ergonomic.

Dynabrade promotes safe tool use with key tips: avoid overinflating wheels, use correct-size pads, respect MOS ratings, and always use guards when required. Lubricate air tools with proper oil, and choose the right dust collection method. Follow ANSI, OSHA, and ISO standards for safety.

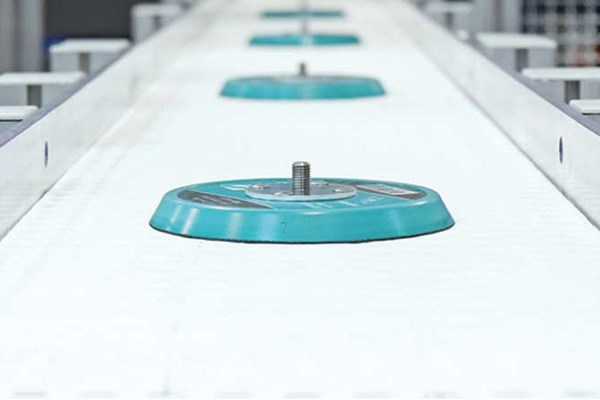

If your Dynabrade sanding pad is worn or damaged, replace it using the included wrench. Always disconnect the air supply first. Dynabrade pads are made in the USA, weight-mated for smooth performance, and tested for durability and safety—ensuring top-quality, swirl-free finishes.

Dynabrade vacuum systems are Class II rated, ideal for collecting combustible dusts. M-Class suits general areas, while Division 1 handles metallic dusts (explosive risk), and Division 2 is for non-metallic dusts. Choosing the right system depends on the dust type and hazard level.

Dynabrade's dust collection systems improve air quality, reduce abrasive use, cut rework, and lower cleaning costs—saving up to $9,787.50 per worker annually. They also support OSHA compliance, protect equipment, and promote a healthier, safer workplace.